MILL ROLL PULLEYS

Mill Roller Pulleys

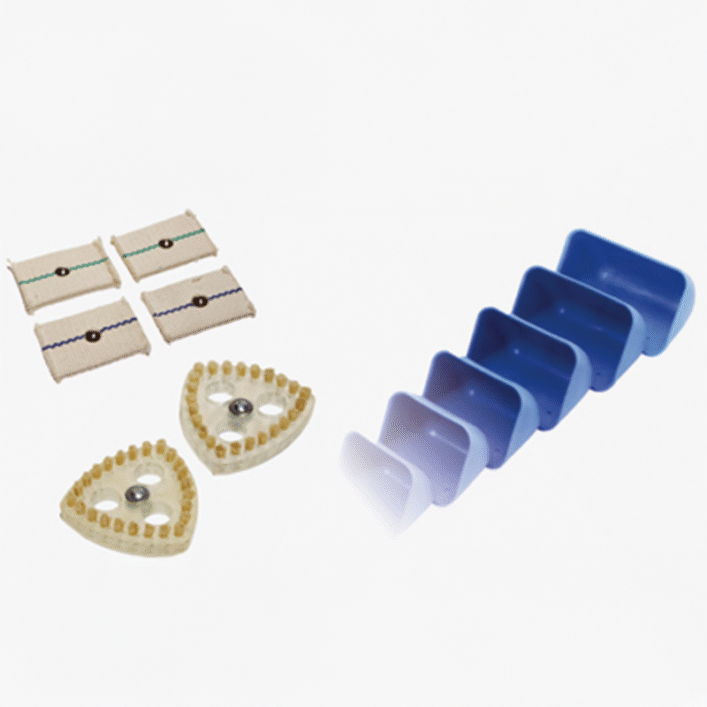

Mill roller pulleys are among the most critical components used in flour mills. Designed to ensure the efficient operation of roller machines and transmit power, these pulleys are produced in different types and dimensions to match system requirements. They are generally classified into two groups: Smooth (Liso) and Breaking (Kırma) pulleys. Both groups are manufactured according to DPL and 8M PK belt types, ensuring complete compatibility with roller systems.

Smooth (Liso) Pulleys

-

Function: Ensure uniform crushing of material and are mainly used for fine grinding.

-

Applications: Flour mills, semolina plants, and other grinding industries.

-

Features: Manufactured to fit both DPL and 8M PK belt types.

Breaking Pulleys

-

Function: Used for crushing hard and coarse materials, ideal for the first stage of grinding.

-

Applications: Agricultural products, mining, and various industrial sectors.

-

Features: Built with high strength, also compatible with DPL and 8M PK belts.

Pulley Types by Belt

DPL Belt Type

-

Features: Offers high flexibility and durability, suitable for light-load applications.

-

Groove Sizes: Produced in 22 and 26 grooves, available in different diameters and sizes.

-

Application: Commonly used in flour and semolina mills.

8M PK Belt Type

-

Features: Known for heavy load capacity and strength, ideal for demanding industrial use.

-

Groove Sizes: Produced in 28 PK and 36 PK options, available in various sizes.

-

Application: Widely used in agriculture, mining, and heavy industry.

Pulley Types and Technical Features

-

By Material

-

Steel: Provides high durability for heavy loads.

-

Cast Iron: Strong and economical, but heavier.

-

Aluminum: Lightweight, corrosion-resistant, and energy efficient.

-

-

Diameter and Speed Ratio

-

Effect of Diameter: Larger diameters generate slower but more powerful motion.

-

Speed Ratio: Correct ratios optimize mill performance.

-

Maintenance and Long Service Life

-

Regular Lubrication: Reduces friction and prevents wear in bearings and moving parts.

-

Balancing: Ensures stable operation, minimizes vibration, and extends service life.

-

Failure Signs: Excessive noise or vibration may indicate imbalance or bearing issues.

Strategies to Enhance Performance

-

Proper Pulley Selection: Matching the right pulley to the system improves efficiency and production capacity.

-

Energy Efficiency: Lightweight pulleys help lower energy consumption.

-

Advanced Technology: Modern designs and materials significantly improve performance.

Production and Quality Control

All our mill roller pulleys are produced with high precision, dynamically balanced, and coated with manganese phosphate to ensure durability and long service life. This guarantees reliable performance in milling operations.

Frequently Asked Questions

-

Why are roller pulleys so important?

They are the “heart” of the milling machine, transferring power efficiently and reducing costs by minimizing energy loss. -

How do they contribute to energy savings?

They minimize power loss, enabling the same production output with lower energy consumption. -

Why does long service life matter?

Durable pulleys reduce maintenance costs and ensure uninterrupted production. -

What maintenance do they require?

Regular cleaning, lubrication, and monitoring of wear signs keep them in optimal condition. -

How can pulley performance be improved?

Using high-quality materials, performing regular maintenance, and choosing energy-efficient designs all optimize performance.

Looking Ahead

With advancing technology, mill roller pulleys are continuously evolving to become more durable and efficient. Future designs and materials are expected to further boost performance and sustainability in milling operations.

Conclusion: Mill roller pulleys are vital components that directly affect the efficiency and quality of production. Using high-quality pulleys ensures energy savings, reduced maintenance costs, and greater customer satisfaction—making them indispensable in modern milling.