MILLING MATERILALS

Milling Materials: Essential Equipment for Enhanced Performance

What Are Milling Materials and Why Are They Important?

Mills transform grains and other raw materials into flour, semolina, and a variety of food products. For mills to operate efficiently and deliver high-quality output, the materials used are of critical importance. These components not only ensure continuous production but also directly impact product quality. In this article, we explore what milling materials are, address common questions, and explain how they improve performance.

What Are Milling Materials?

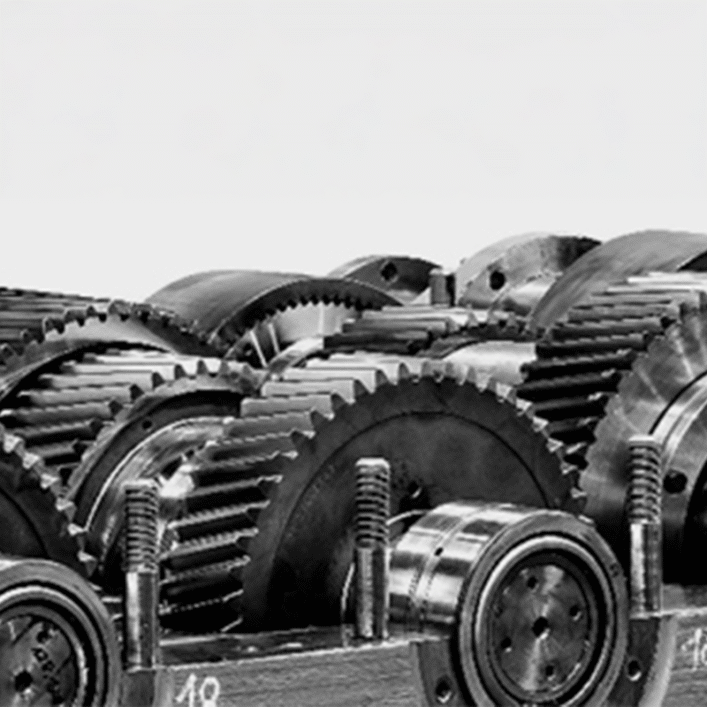

Milling materials include the essential parts and equipment that allow mills to function effectively:

-

Millstones: Used to grind grains and other products. High-quality stones provide finer and more uniform grinding.

-

Roller Pulleys: Ensure roller machines operate efficiently, delivering energy savings and longer service life.

-

Poly V Pulleys: Enhance power transmission and machine performance. Built with durable materials.

-

Bushings and Bearings: Support smooth operation of machine parts and prevent wear.

-

Filtration Systems: Improve the purity and quality of flour and related products, ensuring hygiene and safety.

Improving Efficiency with Milling Materials

High-quality milling materials directly influence efficiency and performance.

-

Premium Stones and Pulleys: Provide effective grinding and save energy.

-

Maintenance and Repair: Regular servicing extends machine life and prevents breakdowns.

-

Effective Filtration: Ensures higher product quality and guarantees food safety.

The Future of Milling Materials

As technology evolves, milling materials are also advancing. Modern materials and innovative designs are creating more durable and sustainable solutions. In the future, milling materials are expected to become even more efficient, further optimizing production processes.

Frequently Asked Questions

1. Why are millstones so important?

They are the most critical element in grain grinding. High-quality stones ensure more consistent grinding, improving product quality and lasting longer with less maintenance.

2. Why are roller pulleys used?

They increase machine efficiency, save energy, and reduce maintenance costs while ensuring reliable performance.

3. What are the advantages of Poly V pulleys?

They deliver high performance, energy efficiency, and long service life. In addition, they enhance machine productivity.

4. Why are bushings and bearings necessary?

They enable smooth operation of machine components, prevent wear, extend machine life, and reduce maintenance costs.

5. Why are filtration systems important?

They ensure flour and other products remain pure and hygienic, improving product quality and protecting food safety.